Project Description

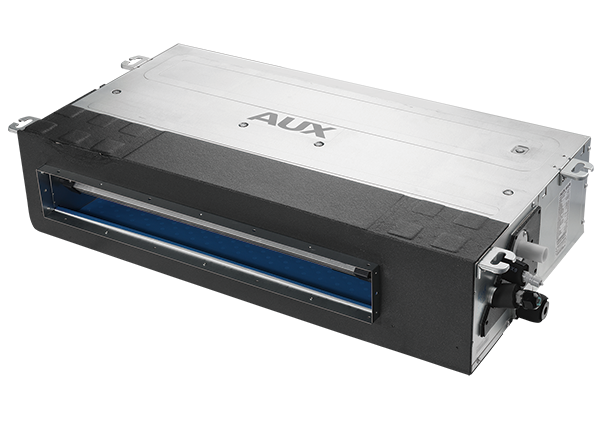

Duct Type

A-Match DC Inverter R32, A++

AUX U-Match DC Inverter R32 Duct Type Series is a 2020 generation unit for compact yet strong and flexible applications packed with several new advantages:

- Wider and stronger Air Flow volume and Static pressure capabilities at lower noise. Variable Static Pressure, can be monitored from the Wired controller.

- Unique Patented AUX Constant Airflow Vol Technology adapts fan speed to installation conditions to achieve constant air flow at duct outlet.

- Equipped with a powerful water pump, able to lift water to up 700mm (models 36+).

- 2020 designed Statice pressure chamber, with reduced air leakage and a new 4-step drain pan, an overall Ultra slim unit with 245mm of height. Completely removable control box.

- R32 DC Inverter GMCC compressors offer a stable and reliable operation even under extreme temperature conditions, such as -15~24 in Cooling and -15 ~52 in Heating.

- Wireless LCD remote control, and Wired controller capability as Optional offer full installation flexibility.

- Ability to connect to WiFi, basing on the special optional WiFi Module.

- AUX Touchscreen Central Controller can control up to 64 sets of units, with grouping, Error codes, Fire Alarm, and running status info.

- New, popup (zero screw) filter section can carry W-type dust filter which is easy-access and faster to clean.

- Fresh Air intake ability.

Specifications

| MODEL CODE | SET | ALMD-H18/NDR3HA | ALMD-H24/NDR3HA | ALMD-H36/NDR3HA | ALMD-H42/NDR3HA | ALMD-H48/SDR3HA | ALMD-H60/SDR3HA | ||||||

| MODEL CODE | IDU | ALMD-H18/NDR3HA | ALMD-H24/NDR3HA | ALMD-H36/NDR3HA | ALMD-H42/NDR3HA | ALMD-H48/SDR3HA | ALMD-H60/SDR3HA | ||||||

| MODEL CODE | ODU | AL-H18/NDR3A(U) | AL-H24/NDR3A(U) | AL-H36/NDR3A(U) | AL-H42/NDR3A(U) | AL-H48/SDR3A(U) | AL-H60/SDR3A(U) | ||||||

| Operation | COOLING | HEATING | COOLING | HEATING | COOLING | HEATING | COOLING | HEATING | COOLING | HEATING | COOLING | HEATING | |

| Nominal Capacity | kW | 5,00 | 5,60 | 7,00 | 8,00 | 10,55 | 11,15 | 12,10 | 13,50 | 14,00 | 16,00 | 16,00 | 17,00 |

| Nominal Capacity | Btu/h | 17.060 | 19.107 | 23.884 | 27.296 | 35.997 | 38.044 | 41.285 | 46.062 | 47.768 | 54.592 | 54.592 | 58.004 |

| Pdesign (C/A/W)* | kW | 5,20 | 4,70 | 7,00 | 7,00 | 10,30 | 8,60 | 10,50 | 8,60 | 14,00 | 12,00 | 15,40 | 12,50 |

| Capacity Range | kW | 1,53 – 5,60 | 1,40 – 6,20 | 2,16 – 8,20 | 1,98 – 9,30 | 2,90 – 13,0 | 2,60 – 13,5 | 2,90 – 13,5 | 2,60 – 15,0 | 4,76 – 16,5 | 4,78 – 16,15 | 4,76 – 17,5 | 4,78 – 18,5 |

| Capacity Range | Btu/h | 5.220~19.107 | 4.777~21.154 | 7.370~27.978 | 6.756~31.732 | 9.895~44.356 | 8.871~46.062 | 9.895~46.062 | 8.871~51.180 | 16.241~56.298 | 16.309~55.104 | 16.241~59.710 | 16.309~63.122 |

| Power Input (nom-max) | kW | 1,63-2,30 | 1,73-2,25 | 2,18-3,56 | 2,10-3,62 | 3,40-4,71 | 3,45-4,13 | 4,50-5,10 | 4,60-4,53 | 5,20-6,70 | 5,40-6,80 | 6,10-6,80 | 5,80-7,10 |

| Current Input (nom-max) | A | 7,16-10,10 | 7,60-9,88 | 9,57-15,63 | 9,22-15,90 | 15,0-21,50 | 15,5-18,00 | 19,50-22,30 | 20,00-19,70 | 22,60-28,60 | 23,40-29,10 | 26,50-29,10 | 25,20-29,50 |

| Annual Consumption | kWh/ann | 294 | 1.617 | 401 | 2.405 | 587 | 2.939 | 599 | 2.940 | – | – | – | – |

| SEER – SCOP(C/A/W) – Energy Class | W/W | 6,30 A++ | – / 4,00A+ / – | 6,60 A++ | – / 4,50A+ / – | 6,10 A++ | – / 4,00A+ / – | 6,20 A++ | – / 4,00A+ / – | 6,20 A++ | – / 4,10A+ / – | 6,20 A++ | – / 4,00A+ / – |

| Ambient Temperature Range | oC | -15 ~ 52℃ | -15 ~ 24℃ | -15 ~ 52℃ | -15 ~ 24℃ | -15 ~ 52℃ | -15 ~ 24℃ | -15 ~ 52℃ | -15 ~ 24℃ | -15 ~ 52℃ | -15 ~ 24℃ | -15 ~ 52℃ | -15 ~ 24℃ |

| Power supply | V-Ph-Hz | 230V ~ 1N – 50 Hz | 230V ~ 1N – 50 Hz | 230V ~ 1N – 50 Hz | 230V ~ 1N – 50 Hz | 400V ~ 3N – 50 Hz | 400V ~ 3N – 50 Hz | ||||||

| Power Connection Cable ODU.-IDU. / Com. | mm2 | 3×2,5 – 3×1,5 / 2×0,75 | 3×2,5 – 3×1,5 / 2×0,75 | 3×4,0 – 3×1,5 / 2×0,75 | 3×4,0 – 3×1,5 / 2×0,75 | 5×2,5 – 3×1,5 / 2×0,75 | 5×2,5 – 3×1,5 / 2×0,75 | ||||||

| Compressor Type | GMCC Rotary | GMCC Rotary | GMCC Rotary | GMCC Rotary | GMCC Rotary | GMCC Rotary | |||||||

| Throttling Method | Electronic Expansion Valve | Electronic Expansion Valve | Electronic Expansion Valve | Electronic Expansion Valve | Electronic Expansion Valve | Electronic Expansion Valve | |||||||

| Air Flow Volume | m3/h | 1.150 / 960 / 840 | 1.400 / 1.190 / 980 | 1.900 / 1.600 / 1.400 | 1.900 / 1.600 / 1.400 | 2.300 / 2.000 / 1.700 | 2.300 / 2.000 / 1.700 | ||||||

| Available static pressure | Pa | 25 (0~160) | 25 (0~160) | 37 (0~160) | 37 (0~160) | 50 (0~160) | 50 (0~160) | ||||||

| Sound Pressure Level IDU (H/M/L) – ODU. | dB(A) | 43 / 41 / 40 – 53 | 44 / 41 / 39 – 58 | 44 / 41 / 39 – 58 | 44 / 41 / 39 – 58 | 52 / 49 / 47 – 60 | 52 / 49 / 47 – 60 | ||||||

| Sound Power IDU (H/M/L) – ODU | dB(A) | 53 (H) – 64 | 55 (H) – 67 | 55 (H) – 66 | 55 (H) – 66 | 64 (H) – 70 | 64 (H) – 70 | ||||||

| Diameter Liquid-Gas Connection Pipe | inch | 1/4″ – 1/2″ | 3/8″ – 5/8″ | 3/8″ – 5/8″ | 3/8″ – 5/8″ | 3/8″ – 3/4″ | 3/8″ – 3/4″ | ||||||

| Refrigerant charge (precharge/after 5m) | R32 – 1,16kg / 30g/m | R32 – 1,40kg / 30g/m | R32 – 2,54kg / 30g/m | R32 – 2,54kg / 30g/m | R32 – 3,60kg / 30g/m | R32 – 3,60kg / 30g/m | |||||||

| Max Distance /Height Connection Pipe | m | 30 / 20 | 50 / 25 | 65 / 30 | 65 / 30 | 65 / 30 | 65 / 30 | ||||||

| Indoor Unit Dimension LxHxD /Weight | mm/kg | 1.000 x 700 x 245 / 31 | 1.000 x 700 x 245 / 32 | 1.400 x 700 x 245 / 42 | 1.400 x 700 x 245 / 42 | 1.400 x 700 x 245 / 42 | 1.400 x 700 x 245 / 42 | ||||||

| Supply air dimension HxL | mm | 874 x 204 – 811 x 175 | 874 x 204 – 811 x 175 | 1.275 x 208 – 1.213 x 178 | 1.275 x 208 – 1.213 x 178 | 1.275 x 208 – 1.213 x 178 | 1.275 x 208 – 1.213 x 178 | ||||||

| Outdoor Unit Dimension LxHxD /Weight | mm/kg | 830 x 545 x 315 / 37 | 900 x 700 x 350 / 51 | 970 x 805 x 395 / 72 | 970 x 805 x 395 / 72 | 940 x 1350 x 370 / 92 | 940 x 1350 x 370 / 92 | ||||||

* Colder, Average, Warmer climate zones for heating operation